The present paper examines the tensile properties of the dragline silk of Araneus diadematus. The objective of our work was to study the behavior of spider filaments under a given stress variation, followed by strain measurements using a test rig that was assembled for this purpose. In the present study, dragline filaments were exposed to both cyclic and long-term static loadings. It was demonstrated that, in order to obtain the outstanding strength properties of a fiber, it is necessary for them to undergo a strengthening procedure. Moreover, a hypothesis concerning the self-organisation properties of spider webs was proposed.

Key words: dragline silk, tensile properties, stress-strain curve, strengthening.

Introduction

Spider web strength is one of its most important characteristics [3,4]. It provides the spider with safe movements in space and determines the success of its hunting. The strength depends both on the internal structure of the fibers and on the external influences that they experience immediately upon leaving the web warts. Studying these dependencies will provide a deeper understanding of the role of the web in the lives of spiders.

In our work, we studied the strength characteristics of spider webs under the influence of tensile force on the example of major ampullate silk (MAS), also known as dragline silk, of Araneus diadematus [9] .

Among all types of spider silk, MAS is the most studied [6,10]. This type of silk is synthesized by large ampullate glands and is used by the spider to build the frame of the web and for locomotion.

The MAS is believed to have the structure and properties of semi-crystalline polymers [6,12]. The fibers are based on proteins MaSp1 and MaSp2 families, which have a molecular mass of 250–400 kDa and contain large amounts of alanine, glycine and proline [8]. The proteins of both families have highly conserved N- and C-terminal domains, while the core contains short repetitive amino acid motifs. The MaSp1 protein is rich in poly-Ala and poly-Gly-Ala repeats, which form heterogeneous beta-layers organized into beta-crystals by means of numerous hydrogen bonds. The crystals are arranged along the fiber’s long axis [11]. The beta layers are interconnected by

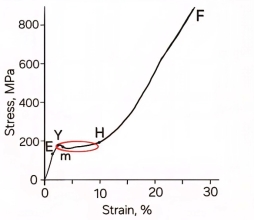

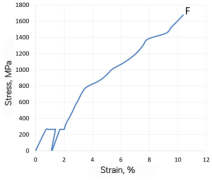

The mechanical characteristics of a fiber are closely related to its molecular structure. Figure 1 shows a typical stress-strain curve of dragline silk, representing the dependence σ = f(ε), where σ is the stress in the fiber, ε is the linear strain:

Fig. 1. Typical stress-strain curve of dragline silk; E — elastic limit, Y — yield point, m — plateau, H — hardening start, F — failure

The presented curve has a peak Y and then a «plateau» m in the plastic deformation region. During the transition from the Y point to the m region in the fiber, deformation-activated destruction of the original structure occurs [1, p.188] due to the breakage of initial hydrogen bonds and the change in the conformation of beta-crystals relative to the fiber axis.

In the m region, the deformation proceeds at constant tension. The transition to the H region means that deformation of the polymer requires an increase in tension. The region H on the stress-strain curve is called the region of polymer hardening [1, p.189].

From the above, it can be concluded that the deformations within the m and H regions result in a harder and stronger fiber.

Usually, scientists vary strain and fix stress in the fiber to study tensile characteristics of the dragline silk [7]. It is relatively difficult to perform such experiments in the absence of specialized equipment. The aim of our work was to study the behavior of spider filaments under a given stress variation followed by strain measurements. Experiments have shown that when reaching the Y point undersuch experimental conditions, even a slight increase in load leads to uncontrolled stretching and consequently failure of the filament. Therefore, in order to move to the m region and subsequently harden the fiber, the loading regime must be changed.

In natural conditions, the web is constantly affected by external force factors, such as the weight of the spider itself, wind, branch movement, and is repeatedly deformed without collapsing [2]. This is probably due to the fact that the web is hardened under the action of tensile forces. It is this hardening property that needs detailed studies and in-situ modelling.

In the following, we will consider spider web fiber as a natural material that has not been pre-strengthened.

Materials and methods

Major ampullate spider silk

The MAS of the spider Araneus diadematus is a bundle of parallel oriented fibers, the diameter of which can be from 3 to 6 μm [10]. The range of static forces causing fiber failure is 5–40 mN [4]. The number of fibers in a filament can be up to two dozen [2]. The total diameter of the MAS filament ranges from 15 to 25 μm and its length can reach 2–3 m [6].

All adjacent fiber layers of the filament are in contact with each other along its entire length, so from a methodological point of view it will be acceptable to carry out the research directly with the filament.

Equipment and research methods

An experimental setup was designed and assembled to carry out the research. The scheme of this setup is shown in Figure 2.

Fig. 2. Schematic diagram of the experimental setup: a — preparation for the experiment, b — carrying out the experiment; 1 — microscope, 2 — slide, 3 — MAS filament, 4 — plate, 5 — draw string, 6 — container; the experimental details may be found in the corresponding references by the authors in the main text

A light microscope with 3 objectives: 4x, 10x and 40x (1) is located in the center of the experimental setup. The microscope is equipped with a digital camera with a magnification of 10x and a 5Mpix sensor mounted in place of the eyepiece. Using the camera software, linear measurements can be made with an error of less than 1 µm.

A 15 cm long slide was used, which allows fixing a filament of a spider web (3) on it and placing a pull from a nylon thread (5). One end of the web is glued to the glass and the other to a movable plastic plate (4) measuring 4x4x0.2 mm. The thread is also glued to the plate (4), and a hook is attached to the other end of the thread. It allows a small plastic container (6) weighing 1.2 g (weight 11.77 mN), in which the load is placed, to be quickly put on and taken off. The mass of the rod and fixing plate was 0.25 g (weight 2.45 mN).

The microscope is mounted on a specially made bed, which allows the entire system to be rotated and fixed in the vertical plane to any angle from 0˚ to 90˚. During testing (Fig. 2b), the filament of the web is positioned vertically and stretched along the slide by a weight. The deformation of the thread is recorded using the microscope by the movement of the edge of the plate.

Two types of weights were used to create the load: mass (0.094

All tests were conducted at a temperature of 22–23

Results

Native strength of the dragline silk

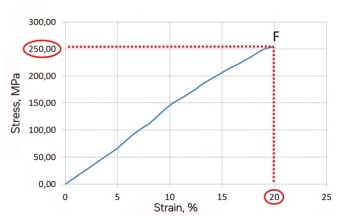

Figure 3 shows the stress-strain diagram of the dragline filament before rupture, plotted from the results of gradual loading with the weights

Fig. 3. Stress-strain curve of the dragline filament under load, F — filament breakage

Immediately draws attention to the comparatively small for MAS filaments strength — 250 MPa, which is significantly less than 1.5–1.7 GPa, which are indicated in many publications [4,5,7]. It can be assumed that the obtained result corresponds to the strength of spider web in natural conditions.

Cyclical load of the MAS filament

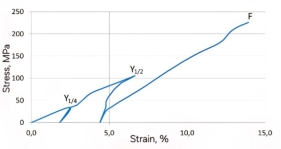

We put forward a hypothesis: the filament would strengthen after passing through cyclic loading. For this purpose, we carried out a series of experiments in which the filament was repeatedly loaded up to about half of the tensile strength obtained in the previous test and then unloaded to 0 MPa. After several cycles, the load was increased until it broke.

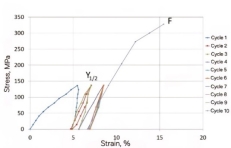

Figure 4a shows the load graph of the MAS filament for 3 cycles and Figure 4b shows the load graph of the MAS filament for 10 cycles. The total test times are 40 min and 60 min, respectively.

It can be noted that in the first case (3 cycles) no noticeable increase in strength was recorded. Significant residual deformations are observed. After 10 cycles there was an increase in the value of tensile strength by 50 %: it was 320 MPa, which is 1.4 times higher than in the previous experiments.

It is assumed that in natural conditions spider web can experience similar stresses, for example, when a branch is deflected. After cyclic stresses, the filament becomes stronger and can withstand sharper and stronger impacts without collapsing.

a)

Fig. 4. a) Stress-strain curve of the MAS filament at 3 load cycles; b) Stress-strain curve of the MAS filament at 10 load cycles; F — filament breakage

Strengthening of the filament under long-term constant loading

We carried out further experiments to study the effect of loading duration on the strength characteristics.

We loaded the filament sequentially in three steps of 21.07 mN each with an interval of 30 s up to 63.21 mN. Thus, a stress of about 240–270 MPa was created in the material, close to the previously found ultimate strength.

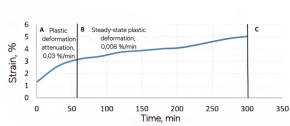

Figure 5a shows the obtained plastic region curve for a time of 5 hours at a stress of 264 MPa.

a)

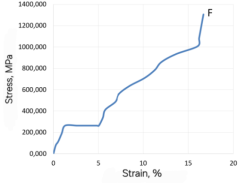

Fig. 5. a) Plastic deformation region of the filament over a time of 5 hours; b) Stress-strain curve of the experiment; F — filament breakage

The average plastic deformation rate at section A — B, which lasted about 60 min, was 0.03 %/min. In section B — C, the plastic deformation rate was approximately 0.008 %/min. The strain of the filament under load for the whole time of the experiment was 5 % and plastic deformation was 4 %.

After 5 hours (loading time), the specimen was loaded to breakage without pause. The resulting stress-strain curve is shown in Figure 5b. The ultimate tensile strength was 1.3 GPa with a filament deformation of almost 17 %. This is 5.2 times higher compared to the first tests.

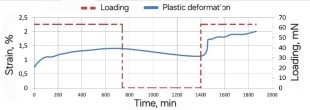

Strengthening of the MAS filament under long-term cyclic loading

In the next test, we loaded the filament with an immediate weight of 63.21 mN. The exposure lasted for 740 min (12h 20 min). We then removed the load. The residual strain measured immediately after the load was removed was 1.4 %. Further 660 min (11 h) the filament was in the unloaded state. After 11 hours, the residual strain was 1.1 %. That is, the tensile strain was almost unchanged (Δ=-0.3 %). After the 11-hour relaxation period, we loaded the filament again for 460 min (7 hr 40 min). In this cycle, plastic deformation increased by 0.9 %. The total plastic deformation was found to be about 2 %. Figure 6a shows the plastic deformation curve under cyclic loading.

The stress-strain diagram obtained in this test is shown in Figure 6b. The tensile strength was 1.7 GPa, which is 6.8 times higher than that of the unstrengthened filament.

a)

Fig. 6. a) Relative elongation versus time under continuous cyclic loading; b) General stress-strain curve under given loading conditions; F — filament breakage

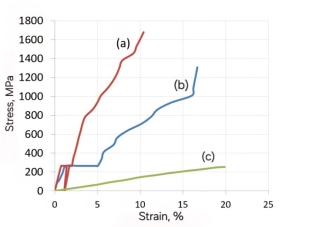

Figure 7 shows graphs demonstrating the difference in the mechanical characteristics of dragline filaments subjected to different hardening regimes. It can be seen that the filament subjected to long-term cyclic loads (Fig. 7, graph a) has a higher ultimate strength compared to other samples (Fig. 7, graphs b, c).

Fig. 7. Comparison of stress-strain characteristics of filaments passed through different loading regimes; a — stress-strain curve of the filament after 20 hours of loading, b –stress-strain curve of the filament after 5 hours of loading, c — stress-strain curve of intact thread

Discussion

The strengthening of the web is considered to be due to changes in its molecular structure. Dynamic and extreme loads lead to the breakage of hydrogen bonds between proteins and the destruction of fibers. However, when the load is removed, beta-crystals have time to rearrange themselves along the fiber axis and form new hydrogen bonds. This hypothesis is confirmed by studies of the internal structure of the spider web in [12]. We suppose, this theory could explain why the long-term loading leads to the hardening of the filament and an increase in its tensile strength.

Our studies allow us to hypothesize the properties of self-organization of the web and its ability to adapt to external factors, including force effects, by modifying its molecular structure.

Conclusion

The paper deals with the stress-strain characteristics of the MAS filaments of the spider web of Araneus diadematus under static and slow dynamic loads. In nature intact spider web can experience similar loads.

We proposed the design of a test rig, which allows setting the required forces and measuring the resulting deformations.

We studied the plastic deformation characteristics of the MAS filament as a function of time and cyclic loading.

We showed that in order to obtain outstanding strength properties of a fiber, it must undergo a strengthening procedure. This can be done by subjecting the fiber to a force, thereby inducing internal rearrangements in the polymer. This strengthening regime increases the tensile strength by more than 6 times.

We find that as the loading time of the fiber increases, the tensile strength of the fiber increases.

References:

- Zezin, A. B. High-molecular compounds: textbook and practice for academic bachelor's degree / A. B. Zezin. — Moscow: Yurait, 2016. — 340 c.

- Denny, M. The physical properties of spider's silk and their role in the design of orb-webs // J. Exp. Biol. — 1976. — Vol. 65. — P. 483–506.

- Elices, M. The hidden link between supercontraction and mechanical behavior of spider silks / Manuel Elices, G. R. Plaza, J. Pérez-Rigueiro, G. V. Guinea // Journal of the Mechanical Behavior of Biomedical Materials. — July 2011. Vol. 4 (Iss. 5), — P. 658–669.

- Ortlepp, C. The scaling of safety factor in spider draglines / C. Ortlepp, J. Gosline // Journal of Experimental Biology. — 2008. — Vol. 211. P. 2832–2840.

- Porter, D. Predicting the mechanical properties of spider silk as a model nanostructured polymer. / D. Porter, F. Vollrath, Z. Shao // European Physical Journal E. — 2005. — Vol. 16 (2). — P. 199–206.

- Rousseau, M.-E. Conformation and orientation of proteins in various types of silk fibers produced by Nephila clavipes spiders / M.-E. Rousseau, T. Lefèvre, M. Pézolet // Biomacromolecules. — 2009. — Vol. 10(10). — P. 2945–2953.

- Wojcieszak, M. Micromechanics of fresh and 30-year-old Nephila inaurata madagascariensis dragline silk / M. Wojcieszak, G. Gouadec, A. Percot et al. // J Mater Sci. — 2017. — Vol. 52, P. 11759–11773.

- Malay, A. D. Complexity of Spider Dragline Silk. / A. D. Malay, HC Craig, J Chen, NA Oktaviani, K Numata // Biomacromolecules — 2022 May 9. — Vol. 23(5). — P. 1827–1840.

- Araneus diadematus // Animal diversity: [site]. — URL: https://animaldiversity.org/accounts/Araneus_diadematus/ (date of reference: 03.03.2025).

- Yarger, J. Uncovering the structure-function relationship in spider silk / J. Yarger, B. Cherry, A. van der Vaart // Nat Rev Mater — 2018. — Vol 3, — P. 18008.

- Jenkins, Janelle E. Solid-state NMR evidence for elastin-like b-turn structure in spider dragline silk / Janelle E. Jenkins, Melinda S. Creager. Creager, Emily B. Butler, Randolph V. Lewis, Jeffery L. Yarger and Gregory P. Holland // Chem. Commun. — 2010. — Vol 46 — P. 6714–6716

- Pérez-Rigueiro, J Basic Principles in the Design of Spider Silk Fibers. / J Pérez-Rigueiro, M Elices, GR Plaza, GV Guinea // Molecules — 2021 Mar 23. — Vol — 26(6), P. 1794.