Introduction

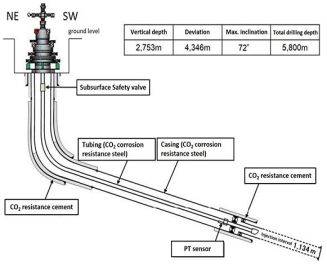

Extended Reach Drilling (ERD) refers to wells with high horizontal displacement relative to vertical depth, often exceeding a Directional Difficulty Index (DDI) of 6.0 for complex profiles. These wells allow operators to tap into distant reservoirs from a single location, reducing environmental impact and costs. However, ERD amplifies hole cleaning issues: cuttings accumulate in the annulus, forming beds that hinder drilling progress and increase equivalent circulating density (ECD). Hydrodynamic processes involve the circulation of drilling fluids (mud) to transport cuttings to the surface. Numerical simulations, such as CFD models, simulate these flows to predict and optimize cleaning without physical trials. This is crucial for ERD, where horizontal sections can span kilometers, and gravity aids less in cuttings removal. Key challenges include high torque/drag, barite sag, and ECD management.

Fig. 1. Schematic diagram of an Extended Reach Drilling (ERD) well profile, illustrating the extended horizontal reach.

Literature Review

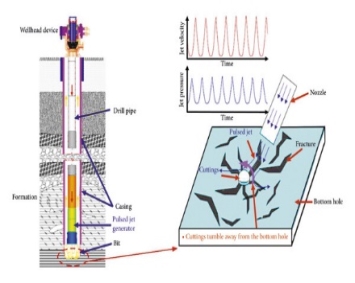

Research on hole cleaning in ERD has evolved from empirical studies to advanced numerical models. Early work focused on experimental flow loops to measure cuttings transport efficiency under varying inclinations and flow rates. For instance, studies have shown that in horizontal wells, cuttings beds form on the low side of the annulus, requiring higher annular velocities for removal. Numerical approaches, including drift-flux models and CFD, have gained prominence. A drift-flux model treats the multiphase flow (fluid, cuttings) as a mixture with relative velocities, enabling transient simulations of cleaning efficiency. CFD simulations, often using Eulerian-Eulerian frameworks, model turbulent flows and particle interactions more precisely. Innovative solutions, like elliptical drill pipes, have been simulated to show up to 18 % improvement in cleaning by inducing secondary flows without excessive pressure drops. Fiber sweeps enhance rheological properties for better suspension. Machine learning models are emerging to predict cleaning based on real-time data.

Fig. 2. Illustration of hole cleaning process in a horizontal wellbore, showing cuttings bed formation and fluid circulation

Methodology: Numerical Simulation Setup

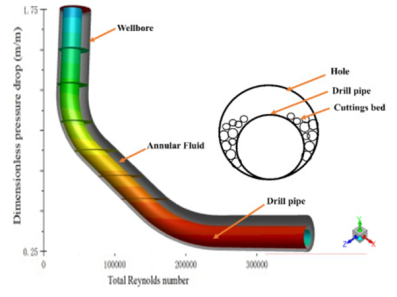

Numerical simulations typically employ CFD software like ANSYS Fluent or Open FOAM to model the annulus as a 3D domain. The geometry includes the drillpipe (inner cylinder) and wellbore (outer cylinder), with lengths simulating ERD sections (e.g., 3000m horizontal). Governing equations are the Navier-Stokes for fluid flow, coupled with particle transport models. For multiphase flow, the Eulerian approach treats cuttings as a granular phase, incorporating drag, lift, and virtual mass forces. Turbulence is modeled via k-ε or k-ω SST for accurate shear predictions. Boundary conditions: Inlet velocity based on pump rates (e.g., 0.5–1.5 m/s annular velocity), outlet pressure, and no-slip walls. Drill pipe rotation (50–150 RPM) and eccentricity (0–100 %) are varied. Mud properties: Non-Newtonian (Herschel-Bulkley model) with yield stress 5–15 Pa, density 1200–1500 kg/m³.

Hydrodynamic Models and Key Parameters

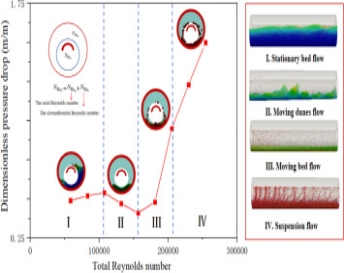

Hydrodynamic processes in hole cleaning involve axial and secondary flows. In ERD, low annular velocities lead to stratified flow, where cuttings settle. Simulations reveal flow patterns: dispersed (effective cleaning), moving bed, or stationary bed.

Key parameters:

Flow Rate: Higher rates increase turbulent kinetic energy, reducing bed height. Optimal annular velocity >0.8 m/s for ERD.

Mud Rheology: Yield stress and plastic viscosity suspend cuttings; fiber additives improve by 10–20 %.

Pipe Rotation: Induces helical flow, eroding beds. 100 RPM can halve bed height.

Eccentricity and Inclination : Eccentric pipes reduce velocity in narrow gaps, worsening cleaning; 80–90° inclinations are critical.

Cuttings Properties: Size (1–5mm) and density affect transport; larger particles require higher velocities.

Fig. 3. CFD simulation visualization of fluid flow patterns in a wellbore annulus during drilling

Results and Analysis

Simulations of a 3000m ERD well show that baseline conditions (0.5 m/s velocity, no rotation) result in 30–40 % bed height, risking stuck pipe. Increasing velocity to 1.0 m/s reduces it to 10 %, but raises ECD by 15 %. With elliptical drillpipe, secondary vortices enhance mixing, improving efficiency by 18 % at similar pressures. Rotation at 120 RPM further cuts bed height by 25 %, as helical paths lift cuttings. Sensitivity analysis: For 85° inclination, eccentricity >50 % doubles bed formation time. Fiber sweeps maintain low beds even at reduced flows. Velocity contours from CFD indicate low-velocity zones on the low side, correlating with bed buildup. Pressure drops remain manageable (<5 % increase) with optimized parameters.

Fig. 4. CFD modeling showing cuttings transport efficiency and bed formation in the annular space during horizontal/ERD drilling

Discussion

Numerical simulations provide a cost-effective way to mitigate ERD risks, outperforming trial-and-error. They reveal trade-offs: higher flows clean better but risk fracturing. Integrating real-time PWD data refines models for adaptive drilling. Limitations include assuming uniform cuttings; real scenarios involve polydisperse particles. Future work: Couple with machine learning for predictive analytics. Case studies from Sakhalin-1 (14km reach) validate simulations in pushing ERD limits.

Conclusion

Effective hole cleaning in ERD wells relies on optimized hydrodynamic processes, best analyzed through numerical simulations. By modeling fluid dynamics and parameters like rotation and rheology, operators can enhance efficiency, reduce downtime, and extend reach. This study underscores the value of CFD in ERD design, paving the way for safer, more economical drilling.

References:

- Sayindla, S., Lund, B., Ytrehus, J. D., & Saasen, A. (2017). Hole-Cleaning and Wellbore Instability in Complex Structural Wells: A Review. The Open Petroleum Engineering Journal, 6, 25–32. https://openpetroleumengineeringjournal.com/VOLUME/6/PAGE/25/PDF

- Sayindla, S., Lund, B., Ytrehus, J. D., & Saasen, A. (2017). Hole-Cleaning and Wellbore Instability in Complex Structural Wells: A Review. The Open Petroleum Engineering Journal, 6, 25–32. https://openpetroleumengineeringjournal.com/VOLUME/6/PAGE/25/PDF

- Gholami, R., Rabiei, M., Rasouli, V., Aadnoy, B., & Nikolaev, N. (2015). A review of the critical conditions required for effective hole cleaning while horizontal drilling. Journal of Petroleum Exploration and Production Technology, 5(4), 379–390. https://doi.org/10.1016/j.ptlrs.2015.10.005

- Sun, Y., Song, X., Guo, Z., Xiang, Y., Wang, Z., & Li, G. (2024). Numerical investigation of flow patterns in cuttings transport for extended-reach horizontal wells with rotation drill pipe. Powder Technology, 438, 119624. https://doi.org/10.1016/j.powtec.2024.119624

- e, Z., Liu, J., Liu, X., & Zhang, Y. (2023). Numerical Simulation of Hole Cleaning of a Horizontal Wellbore Model with Breakout Enlargement Section. Mathematics, 11(14), 3070. https://doi.org/10.3390/math11143070

- Abbas, A. K., Alsaba, M. T., Al Dishdashi, M. F., & Flori, R. E. (2022). Numerical Simulation of Effective Hole Cleaning by Using an Innovative Elliptical Drill pipe in Horizontal Wellbore. Energies, 15(2), 399. https://doi.org/10.3390/en15020399

- Liu, Y., Li, G., Song, X., & Wang, Z. (2023). A novel transient hole cleaning algorithm for horizontal wells based on drift-flux model. Greenery Science and Engineering, 223, 211537. https://doi.org/10.1016/j.geoen.2023.211537

- Walker, M. W. (2012). Extended-Reach Drilling (ERD)—The Main Problems and Current Achievements. Journal of Petroleum Engineering, 2012, Article ID 304320. https://doi.org/10.1155/2012/304320 (PDF available at https://pdfs.semanticscholar.org/6d68/fc2bb68649abe4b488b406f1a4f378fcc824.pdf)

- JAPEX. (n.d.). Extended Reach Drilling (ERD). Japan Petroleum Exploration Co., Ltd. https://www.japex.co.jp/en/technology/advanced/erd

- Cameron, C. (2001). Pressure-While-Drilling Measurements to Solve Extended-Reach Drilling Problems on Alaska's North Slope. SPE Drilling & Completion , 17(02), 100–106. https://doi.org/10.2118/109126-PA

- Baldino, S., Osgouei, R. E., Ozbayoglu, E., Miska, S. Z., May, R., Takach, N., & McLean, A. (2009). Fiber Sweeps for Hole Cleaning. SPE Drilling & Completion, 24(04), 564–570. https://doi.org/10.2118/119162-PA