This study investigates the behavior and bearing capacity of precast driven concrete piles installed under the complex geological and climatic conditions of Astana, Kazakhstan. Dynamic load test data from five several construction sites are analyzed with PLAXIS 2D numerical simulations to evaluate the effect of close space piles from each other and soil densification on load-bearing. Results show significant difference in pile bearing capacity when driven in closed space, particularly in granular soils. It confirms the need to integrate empirical testing, numerical simulation, and local code considerations for optimal design. The findings provide practical insights for modernizing Kazakhstan’s foundation engineering practices.

Keywords: pile foundations, dynamic load testing, PLAXIS 2D, soil densification, Astana, bearing capacity.

1. Introduction

Background of the study Pile foundations serve as important civil engineering elements for projects located in areas with weak surface soils that cannot bear structural loads [1]. The use of pile foundations is essential for Astana Kazakhstan because its huge amount of construction is going on weak soil of this city [2]. The construction industry in Kazakhstan uses driven precast concrete piles because they are strong, consistent, and can go through soft or loose soil and easy to use [3]. The bearing capacity of pile foundations depends on multiple variables like soil type, pile geometry, installation methods and the «group effect» that occurs when piles are closely spaced. The assessment of pile bearing capacity by static load testing requires a lot of time and financial resources even it gives precise results [4]. Dynamic load testing (DLT) follows GOST 5686–2012 [8] and ASTM D4945 [9] standards. It helps estimate pile bearing capacity quickly. This is done by analyzing how waves move through the pile and how the pile reacts to impact [5]. This paper investigates dynamic load testing of pile foundations during real construction work in Astana. It studies how pile bearing capacity and soil behavior change. The analysis uses PLAXIS 2D modeling and test results from different sites, focusing on how close the piles are to each other.

2. Methodology

The methodology used in this study integrates field data, dynamic load testing, analytical calculations, and numerical modeling. The goal is to evaluate the bearing capacity of pile foundations under the complex engineering and geological conditions of Astana. The study seeks to capture the interaction between soil and piles, particularly under close spaced installation scenarios. The process began with characterizing the subsurface soil profiles using borehole data. Then, dynamic load tests were conducted on precast driven piles to assess their bearing capacity. Finally, different pile arrangements were simulated in PLAXIS 2D to analyze pile-soil interaction. All testing and modeling procedures were designed in accordance with relevant standards, including GOST 5686–2012 and guidelines derived from site-specific geotechnical reports.

2.1 Site Description and Soil Properties

Geological and climatic conditions in Astana are complex, with deep seasonal frost penetration, layered soil strata, and variable groundwater levels. Based on multiple geotechnical reports (FTK Modex, Aytmatova, Capital Park), the subsurface typically comprises clay, sandy soils, and dense mixed layers. The following table summarizes the generalized geotechnical properties used in analysis. As shown below in the table 1, Soil Stratigraphy and Engineering Parameters based on field report (FTK Modex).

Table 1

Soil Stratigraphy and Engineering Parameters (FTK Modex)

|

Layer No. |

Soil Type |

Depth Range (m) |

Unit Weight γ (kN/m³) |

Cohesion c (kPa) |

Friction Angle φ (°) |

Modulus E (MPa) |

Remarks |

|

1 |

Clay |

0–3 |

18.0 |

20 |

16 |

6–8 |

Soft to firm |

|

2 |

Silty Sand |

3–7 |

19.5 |

5 |

28 |

15–22 |

Medium density |

|

3 |

Dense Gravelly Sand |

7–12 |

21.0 |

2 |

36 |

35–50 |

Dense layer; high bearing |

2.2 Field Testing

Dynamic Load Testing (DLT) was conducted at several locations: Akbulak Rivera, Capital Park, Aytmatova, Aru Park, and Atlant 5. A total of 71 driven precast concrete piles were tested in accordance with GOST 5686–2012 standards using MSDSh-2500 hammers. Test parameters included drop height, blow count, final set, and redriving outcomes. Additional field data were also available, including borehole characteristics and the exact locations where dynamic load tests were performed on the pile foundations. The collected data were analyzed using software such as Excel to perform the necessary calculations.

Equipment & Procedure:

— Hammer mass: 2,500–3,000 kg

— Drop height: 1.2 m

— Pile type: Precast reinforced concrete (C9–30, C10–30, C12–30)

— Lengths: 6 to 12 m

— Re-driving after 3 days rest

— Capacities analyzed using excel

Results showed:

— Capacity increase of 10–18 % after rest

— Maximum measured capacity at FTK Modex site: 1800 kN

— Lowest capacity in cohesive clays (Aru Park): ~950 kN

2.3 Numerical Simulation

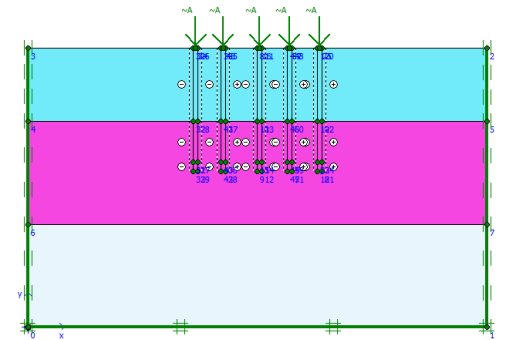

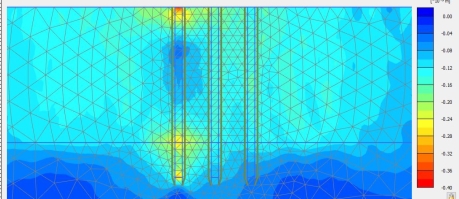

For a better model, the boundary size of 30 m length and 20 m height was considered, which was divided into 3 layers: clay, sand, and dense gravel sand, based on the FTX Modex field report. The properties of each layer and the characteristics of the pile were derived from the field report. The length of the pile was considered 9 m with 30x30 cm cross section as in the field. As shown in Figure 1, the PLAXIS model incorporates five piles embedded in three distinct soil layers.

Fig. 1. PLAXIS 2D-model showing five driven piles and three soil layers under dynamic loading

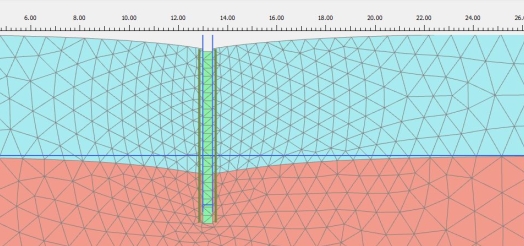

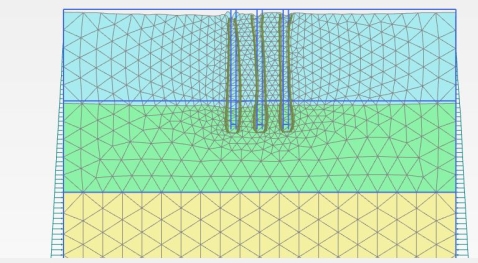

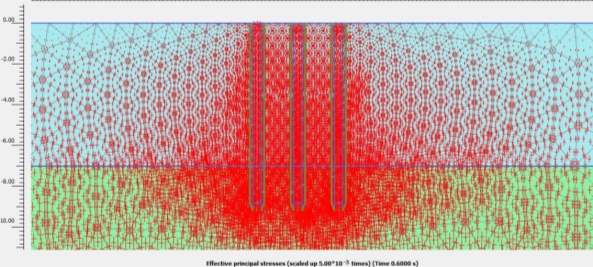

Plaxis 2D was used to model the close spacing of each pile and their effect on each other, and to observe the interaction of soil between each pile. First, a single pile was driven, and then two others were added at a 3-meter distance from each other. Afterward, two more piles were installed between the previously installed piles with a 1.5-meter distance to observe the interaction and close-proximity observations. Refined mesh settings were applied around the pile shaft to capture stress concentration accurately. Figure 2 provides a detailed view of the mesh showing single pile within the layered soil profile.

Fig. 2. Deformation mesh of a single pile under dynamic load, highlighting soil displacement in layered soil conditions

Figure 3 provides a detailed view of the mesh showing pile arrangement within the layered soil profile.

Fig. 3.PLAXIS 2D mesh showing group pile arrangement in three soil layers: clay (top), sand (middle), and dense gravel

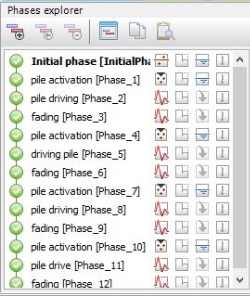

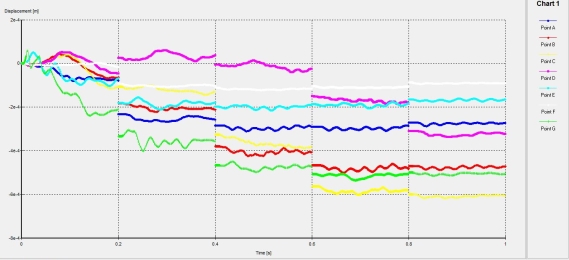

For a realistic simulation and calculation three stage were considered for each pile:

— Pile selection: where piles were selected,

— Pile deriving: the dynamic load was activated

— Fading: the dynamic pile was deactivated to observe settlement response

The dynamic load specified 120kN according to the field report, these phases allowed for clear observation of load-induced deformation, pile-soil interaction, displacement over time. Simulation stages are shown in Figure 4, which visualizes the PLAXIS Phases Explorer output.

Fig. 4. PLAXIS 2D Phases Explorer showing sequential simulation stages including initial conditions, pile activation, dynamic driving, and fading phases for group pile modeling.

3. Results and Discussion

These chapter present the result of field test, numerical simulation using Plaxis 2D, and theoretical calculation for determining the bearing capacity of pile foundation in Astana. The goal is to see how the soil type, pile spacing effect the pile foundation performance.

3.1 Field Test Findings

Dynamic Load Testing (DLT) performed across several sites in Astana—like Capital Park, Aru Park, Akbulak Rivera, and Atlant 5, they show different value of bearing capacity due to the soil type. The bearing capacity of piles is raged from approximately 950kN in cohesive clay in (Aru Park) to 1800 kN in dense gravel in sand, according to field data (FTK Modex)

Redriving after 72 hours rest according the code gost led to a noticeable improvement in bearing capacity 10–18 %) (FTK Modex) due to the pore pressure dissipation. pile installed in sand and dense gravel demonstrates high value of bearing capacity due soil type on shaft friction and end bearing.

3.2 Numerical Simulation Results

The geometry used for the PLAXIS simulation is shown in Figure 1, which includes five driven piles embedded in stratified layers of clay, sand, and dense gravelly sand.

PLAXIS 2D modeling was conducted for multiple scenarios to replicate pile–soil interaction and to assess the effect of pile proximity on overall behavior. The total vertical displacement after group pile activation is illustrated in Figure 5.

As illustrated in Figure 2, the mesh configuration for the single pile case (Fd1) clearly shows stress concentration around the shaft and tip zones under loading. The mesh for the grouped piles, shown in Figure 3, highlights the layout used to simulate 15 % and 30 % densification scenarios in Fd2 and Fd3, respectively.

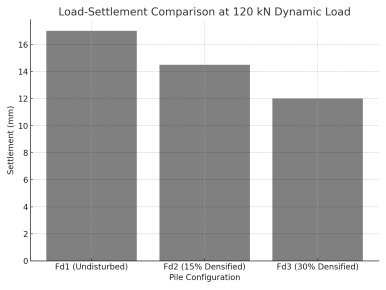

The three main simulation cases considered are as follows:

— Fd1: Single pile in undisturbed soil

— Fd2: Pile placed after adjacent pile installation (15 % densification assumed)

— Fd3: Pile in densified soil due to surrounding piles (30 % densification assumed)

As simulation shown in figure 5.

Fig. 5. Load-settlement comparison at 120 kN dynamic load for three pile configurations: Fd1 (undisturbed), Fd2 (15 % densified), and Fd3 (30 % densified).

Load-settlement behavior:

— Fd1: 17 mm settlement at 120 kN dynamic load

— Fd2: 14.5 mm settlement at similar load

— Fd3: 12 mm settlement, reflecting improved soil conditions and reduced displacement

The simulation also revealed increased stress concentration below the pile tip and along the shaft, especially in Fd3. The bar chart in Figure 6 compares settlements across the three configurations.

Fig. 6. Load-settlement comparison at 120 kN dynamic load for three pile configurations: Fd1 (undisturbed), Fd2 (15 % densified), and Fd3 (30 % densified)

As seen in Figure 7, group pile activation resulted in reduced total displacement compared to the single pile.

Fig. 7. Total displacement after group pile activation.

These patterns confirmed enhanced shaft friction due to densification effects. As shown in figure 8.

Fig. 8. Mean stress concentration beneath pile caps in closely spaced configuration

An analytical calculation of pile bearing capacity was conducted using typical soil parameters from field reports:

— Pile length: 9 m; Cross-section: 0.3 × 0.3 m

— Skin friction values: Clay = 15 kPa, Sand = 35 kPa, Gravel = 55 kPa

— End bearing capacity in gravel: 17250 kPa

Calculated values:

— Skin resistance (Qs): 354 kN

— End bearing (Qb): 1552.5 kN

— Total capacity (Qu): 1906.5 kN

— Design capacity (Qd): ≈ 1362 kN (using safety factor 1.4)

These results aligned closely with both DLT outcomes and PLAXIS results. It confirms the reliability of the adopted parameters and the effect of soil improvement on bearing capacity of soil.

3.4 Engineering Implications

— Piles driven in granular soils benefit significantly from the group effect, because surrounding soil becomes denser, which leads to better friction and less settlement.

— Rest periods after initial driving are critical for accurate capacity evaluation due to pore pressure dissipation in soil.

— PLAXIS 2D simulations provide realistic estimates and it helps to visualize stress distribution, and offer a powerful tool for optimizing pile layout in similar geological conditions.

The field and modeling results suggest the need to update Kazakhstan’s pile design codes to include considerations for group effects and to promote dynamic testing as a validation tool in construction practices. Redriving increased pile capacity by 8–18 % due to pore pressure dissipation and soil setup. Highest performance was observed in sandy and gravelly layers.

4. Conclusions

This study confirms that pile bearing capacity in Astana is significantly influenced by soil type, installation quality, and pile grouping. Field data and numerical simulations demonstrate that: — Closely spaced piles densify surrounding soil, and it increase the shaft friction and reducing settlement. — DLT is essential for real-time validation, especially post-redriving. — Although PLAXIS models, was idealized, it helps to visualize group effects and stress distribution. Recommendations include updating Kazakhstan’s design codes to incorporate group interaction effects and encourage performance-based foundation design.

References:

- Pile foundations in engineering practice [Текст] / S. Prakash, H. D. Sharma. — New York: Wiley, 1990. — 734 с.

- Comparison of the results of different types of testing piles with static load to predict the load capacity of piles [Text] / Abdulla Omarov, Askar Zhussupbekov, Victor Kaliakin, Der-Wen Chang, Dhanya, J. S. // 淡江理工學刊. https://doi.org/10.6180/jase.202501_28(1).0016

- Geotechnical Geo-Information System of Astana [Text] / A.Zh. Zhussupbekov, N. T. Alibekova, S. B. Akhazhanov, N. U. Shakirova, A. B. Alpyssova // Soil Mechanics and Foundation Engineering. — 2019. — Vol. 55, No. 6. — P. 420–424. https://doi.org/10.1007/s11204–019–09558-x

- Foundation design: principles and practices [Текст] / D. P. Coduto, W. A. Kitch, M. R. Yeung. — Boston: Pearson, 2016. — 960 с.

- Field observations of the thermal stability of permafrost under buildings with an underfloor open ventilation space and pile foundations in warm permafrost at high altitudes [Text] / X. Hou, J. Chen, Y. Sheng, P.-F. Rui, Y.-Q. Liu, S.-H. Zhang, T.-C. Dong, J.-W. Gao // Advances in Climate Change Research. — 2023. — Vol. 14, No. 2. — P. 267–275. https://doi.org/10.1016/j.accre.2023.03.004

- Site investigation and soil conditions [Text] / R. Rajapakse // Pile Design and Construction Rules of ThumbElsevier, 2016. — P. 1–30. https://doi.org/10.1016/B978–0–12–804202–1.00001–2

- SP RK 5.01–103–2013. Construction Norms and Rules of the Republic of Kazakhstan.

- GOST 5686–2012. Soil. Methods of Field Testing by Static and Dynamic Loading.

- European Committee for Standardization. Eurocode 7: Geotechnical Design — Part 1: General Rules, EN 1997–1:2004 + A1:2013.